We hold the conviction that quality should never be compromised, whether for residential or commercial applications. We ensure that all our products are using top-tier materials and adhere to superior manufacturing processes.

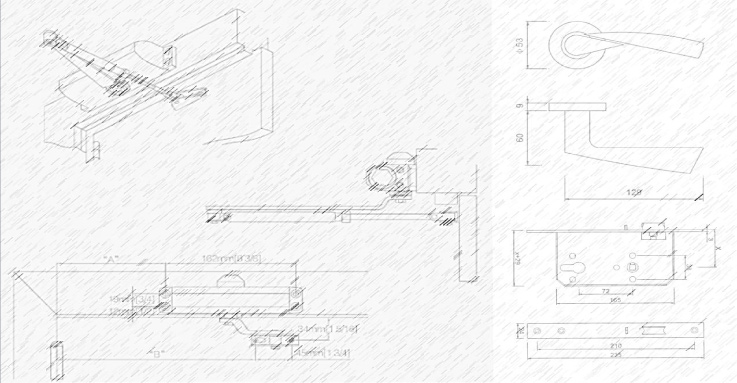

Design Stage – In order to assure the item final product, all process starts with identification of the required size, shape and finish of each item. Most products are produced based on the available templates and quality and performance standards.

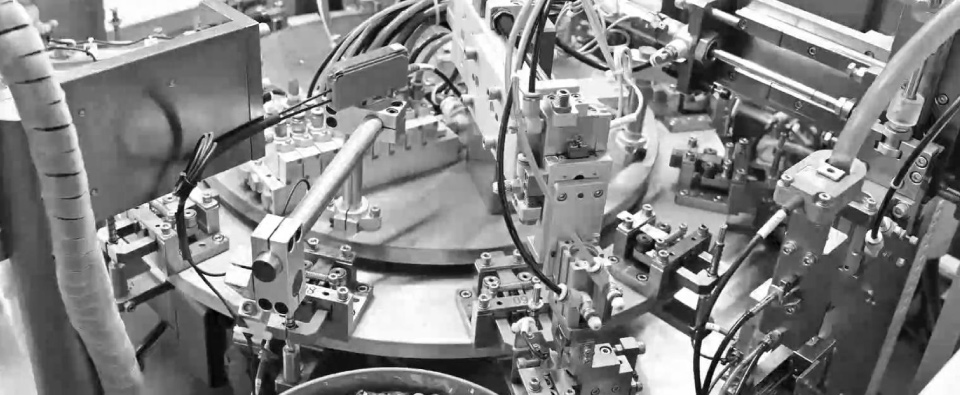

Machining Stage – This step is essential to guarantee that the materials are properly flattened, shaped, or cut into the product component. Some processes are CASTING, EXTRUSION, DEFORMATION & CUTTING

Finishing Stage – Finishing processes like smoothing, burnishing, polishing, and painting can improve the aesthetic appeal of the product, some are enhanced with rust-proofing which can extend their lifespan.

Assembly Stage – A number of components are meticulously assembled to create the final product before it is sent for quality inspection and packaging.

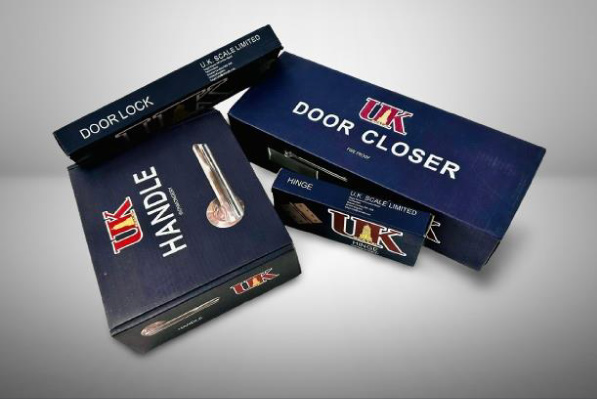

Packing Stage – While many might assume that packing the product is simple, it is actually a crucial aspect of the product itself. Packaging not only protects the product and facilitates easy transportation, but it also serves as a powerful promotional tool.